bending 16 gauge sheet metal Bending sheet metal is a meticulous process. It involves a series of steps, starting from picking the correct type of metal, marking the bend lines, securing the metal on a bending brake, and finally applying the right amount of pressure to make . Yizhong Hardware offers one shop for all your production metal parts. We provide CNC machined parts, plastic products and related services. Highly skilled people are at the heart of Yizhong Hardware Parts′ success, and they make our company unique in the industry.

0 · sheet metal bending standards

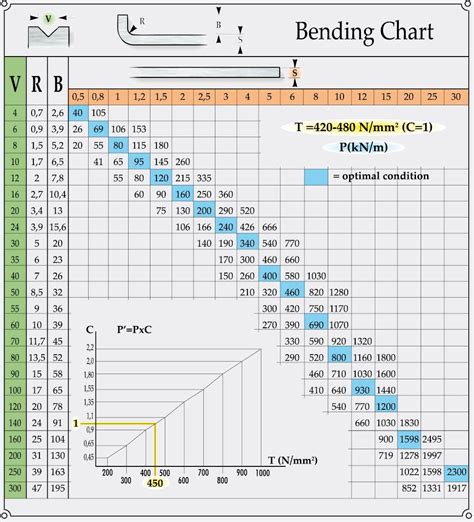

1 · sheet metal bending chart

2 · sheet metal bend allowance chart

3 · bending sheet metal by hand

4 · bending aluminum sheet without brake

5 · bend sheet metal without brake

6 · bend metal without a brake

7 · basics of metal bending

Wholesale Sheet Metal is celebrating 30 great years of serving the Kansas City area! We want to thank all of our customers for their continued support over the years. Join us for lunch Thursday, September 24 from 11:30 until the food runs out to celebrate!

sheet metal bending standards

Bending 16 gauge sheet metal requires the right tools, techniques, and safety measures to achieve accurate and clean bends. With the steps outlined in this article, you can bend sheet metal like a pro. How To Bend Sheet Metal Without A Brake:How To Bend Sheet Metal Without A Brake in 4 different methods with minimal or homemade tools.-----. Here's a cool trick for bending thin-gauge sheet metal with. If you've got scrap sheet metal around, you can put it to use in projects to save material costs.Here are a few tips that will let you make accurate, clean, and professional-looking bends when you’re working with sheet metal. Some materials are .

Bending sheet metal is a meticulous process. It involves a series of steps, starting from picking the correct type of metal, marking the bend lines, securing the metal on a bending brake, and finally applying the right amount of pressure to make . Sheet metal bending can be done using many methods. We discuss those along with springback, bend allowances, k factor, design tips etc.

9 piece warehouse steel cabinet group

Finding the minimum bend radius for steel or aluminum plate requires a little research. Learn how to bend metal and about bending steel plate and aluminum.How To Bend Sheet Metal With Common Tools If you've got scrap sheet metal around, you can put it to use in projects to save material costs. Here's a cool trick for bending thin-gauge sheet metal without needing a brake. your best bet, if you're determined to do it yourself, is to probably try rigging up some type of bending brake. perhaps clamping it to the edge of a workbench and using a . Bending 16 gauge sheet metal requires the right tools, techniques, and safety measures to achieve accurate and clean bends. With the steps outlined in this article, you can bend sheet metal like a pro.

How To Bend Sheet Metal Without A Brake:How To Bend Sheet Metal Without A Brake in 4 different methods with minimal or homemade tools.-----. Here's a cool trick for bending thin-gauge sheet metal with. If you've got scrap sheet metal around, you can put it to use in projects to save material costs.

Bending sheet metal by hand is a manageable task if the piece of sheet metal is small and thin enough to handle. Learn how to bend sheet metal so you can complete home and hobby projects easily without using a sheet metal brake.Here are a few tips that will let you make accurate, clean, and professional-looking bends when you’re working with sheet metal. Some materials are more malleable than others. That means that some will bend, whereas others will weaken and crack.Bending sheet metal is a meticulous process. It involves a series of steps, starting from picking the correct type of metal, marking the bend lines, securing the metal on a bending brake, and finally applying the right amount of pressure to make the bend. Sheet metal bending can be done using many methods. We discuss those along with springback, bend allowances, k factor, design tips etc.

Finding the minimum bend radius for steel or aluminum plate requires a little research. Learn how to bend metal and about bending steel plate and aluminum.

How To Bend Sheet Metal With Common Tools If you've got scrap sheet metal around, you can put it to use in projects to save material costs. Here's a cool trick for bending thin-gauge sheet metal without needing a brake.

your best bet, if you're determined to do it yourself, is to probably try rigging up some type of bending brake. perhaps clamping it to the edge of a workbench and using a hammer to work it to a 90 degree bend. you're gonna have a . Bending 16 gauge sheet metal requires the right tools, techniques, and safety measures to achieve accurate and clean bends. With the steps outlined in this article, you can bend sheet metal like a pro. How To Bend Sheet Metal Without A Brake:How To Bend Sheet Metal Without A Brake in 4 different methods with minimal or homemade tools.-----.

sheet metal bending chart

Here's a cool trick for bending thin-gauge sheet metal with. If you've got scrap sheet metal around, you can put it to use in projects to save material costs. Bending sheet metal by hand is a manageable task if the piece of sheet metal is small and thin enough to handle. Learn how to bend sheet metal so you can complete home and hobby projects easily without using a sheet metal brake.

Here are a few tips that will let you make accurate, clean, and professional-looking bends when you’re working with sheet metal. Some materials are more malleable than others. That means that some will bend, whereas others will weaken and crack.Bending sheet metal is a meticulous process. It involves a series of steps, starting from picking the correct type of metal, marking the bend lines, securing the metal on a bending brake, and finally applying the right amount of pressure to make the bend. Sheet metal bending can be done using many methods. We discuss those along with springback, bend allowances, k factor, design tips etc. Finding the minimum bend radius for steel or aluminum plate requires a little research. Learn how to bend metal and about bending steel plate and aluminum.

How To Bend Sheet Metal With Common Tools If you've got scrap sheet metal around, you can put it to use in projects to save material costs. Here's a cool trick for bending thin-gauge sheet metal without needing a brake.

sheet metal bend allowance chart

bending sheet metal by hand

2 reviews of WHOLESALE SHEET METAL "Visited today for the first time. Salesman was helpful & clear, fairly patient too given how busy everyone is right now. Had to go home to finalize the design for a fairly complex plenum but they acted like .

bending 16 gauge sheet metal|sheet metal bend allowance chart